Don’t Give Bacteria Shelter in Your Food Plant Floor

Don’t Give Bacteria Shelter in Your Food Plant Floor

Each year over 500 people die and 2,500 become seriously ill from food borne diseases after ingesting bacteria contaminated food. According to research conducted by the American Meat Institute, 39% of positive bacteria swab readings occur on the floors of food processing facilities. While there is no substitute for vigilant sanitation, good design can contribute to reduction and elimination of bacteria contaminants.

Though favored in the food processing industry for their longevity, red shale acid brick pavers and quarry tile flooring leave something to be desired when it comes to cleanliness. To achieve a slip resistant surface, these bricks and tiles are typically wire-cut or treated with surface applied grit. Wire cutting tears the surface of the bricks leaving open pores during their manufacture. Surface embedded grit can be dislodged with wear leaving craters behind. These pores and craters inherently retain proteins and processing fluids that can create septic conditions. Even with the strictest sanitation procedures, deeper pores do not lend themselves to complete removal of septic bacteria.

Through thoughtful selection of food plant flooring materials, specifiers can avoid introducing bacteria harborage sites without sacrificing the finish’s longevity. Non-porous and non-absorbent vitrified industrial tiling long used in Europe is now commercially available in North America. With molded surface textures for various static coefficients of friction, vitrified tiles are absent the pores and craters inherent in red shale acid brick pavers and quarry tile. And their higher impact resistance reduces the risk of chipping and shelling over the floor’s life.

When specified in combination with innovative, high-productivity vibration setting and power grouting installation techniques, fully vitrified tile flooring systems can achieve unsurpassed flatness, virtually eliminating problematic kick-ups and lips common with conventionally set brick and tile finishes. To further reduce potential bacteria harborage sites, consider specifying fully vitrified tiles with built-in 2 mm side joint spacers, which narrow the typical 1/8- to 1/4-inch wide side joints by 50 to 70%.

The last word: Leveling courses, commonly made of Portland cement, latex-modified, or epoxy polymer concrete, also deserve attention when selecting floor materials for systemic bacteria control. Many industrial tile installers favor dry, Portland Cement based fill for sloping floors, yet these underlayments tend to have relatively low strength and high porosity. Latex-modified or epoxy based underlayments ensure sufficient compressive strength for long term durability while avoiding introduction of hidden and inaccessible bacteria harborage sites.

Porosity Killed the Cat

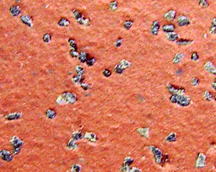

During the manufacture of vertical fiber brick, sometimes referred to as “dairy brick,” the top surface of the brick is cut with a wire, which tears it to impart a rough texture for slip resistance. The resulting surface pores could harbor bacteria.

1000 Grains of Sand

Into the surface of this acid brick paver, cinders are embedded during production to impart a slip resistant profile. Wear and tear can dislodge the cinders, leaving behind potential bacteria harborages and compromised slip resistance.

Safety Without Sacrificing Cleanability

Safety Without Sacrificing Cleanability

Dust-pressed vitrified tiles are non-porous, antimicrobial, and are available in a range of colors and surface textures. The Orange Peel surface shown provides resistance to static friction similar to that of a double-abrasive acid brick paver. Integrally molded, the surface retains its slip-resistant texture.