Seal Sewer Structures Securely with HDPE

Seal Sewer Structures Securely with HDPE

I’m sure this has never happened anywhere you’ve worked, but have you heard of a friend of a friend, who discovered that their plant process sewers were leaking? Sewers can be a major drain on maintenance budgets when they go bad. Bypass-pumping costs can add up and, for some reason, despite this cost, no one seems anxious to dig up pipes and fix them. What if they discover that the soil is contaminated? Again, we’re not talking about anywhere you have worked, but maybe somewhere your cousin’s neighbor’s kid used to work. Read on to learn how high-density polyethylene (HDPE) can seal sewer structures securely.

High-density polyethylene has gained favor as a material of construction for chemical process sewers. It offers broad chemical resistance and lends itself to a variety of installation techniques from open cut construction to trenchless technologies like slip-lining, pipe bursting, directional drilling, and fold-and-form relining. There are lots of ways to get HDPE into your sewers and eliminate the old segmented concrete or vitreous clay leakers, but what about the manholes and lift stations?

To achieve a bottle-tight sewer—and keep sewers off the environmental manager’s radar—sewer appurtenances can be likewise lined with HDPE, avoiding dissimilar material interfaces and leaky mechanical seals between pipes and pits. Anchored thermoplastic liners, available in HDPE, as well as polypropylene, polyvinylidene fluoride, and ethylene and chlorortrifluoroethylene copolymer, can be used to line the insides of concrete forms to seal cast-in-place or precast structures.

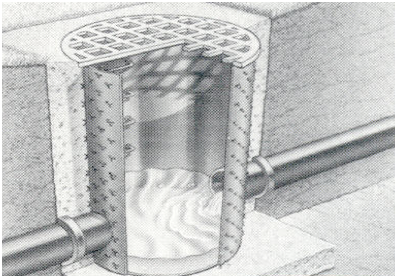

Using these HDPE liners in conjunction with HDPE pipe or pipe liners enables the two to be welded together for a permanent, bottle-tight seal. And, when properly specified and installed, anchored HDPE liners can be reasonably expected to outperform coating alternatives.

Safely Sealed - Flanged or unflanged HDPE pipe stub-outs can be welded to HDPE manhole liners for a leak-tight connection.

Top 5 Advantages of Anchored HDPE Liners over Concrete Coatings

- Longer expected service life

- Resistant to hydrostatic groundwater backpressure/delamination

- Suitable for installation during cold to very hot weather

- Can be prefabricated, precast to save construction time

- Can be welded to inlet pipes, trenches for leak-tight seal

1. Longer expected service life

In the chemical industry, a service life of greater than 25 years is attributed to anchored HDPE liners. Common causes of premature failure are temperature excursions during periods of high groundwater and changes in the effluent chemistry. Poor quality installation techniques—incomplete consolidation of the concrete or grout behind the liner, nail holes left from the formwork—could also lead to premature failure. To mitigate temperature related failures, designers must be mindful of the potential for steam or steam condensate to discharge into the sewer system, either in large volume or into an empty sewer in small but continuous volumes. Engineering controls, such as a quench system or retention pit, could be employed to cool hot effluent streams.

2. Resistant to hydrostatic groundwater backpressure/delamination

Before liquid coatings are applied to concrete sewer structures, the concrete is cleaned and abraded or etched to create a surface profile, increasing the surface area to which the coating might adhere. Chemical contamination, moisture, or inadequate profile can interfere with the coating’s adhesion. Add hydrostatic backpressure to a marginally bonded coating, and the coating will likely delaminate or crack.

Anchored HDPE liners do not rely on this type of surface adhesion. The liners are mechanically locked into the concrete surface by means of numerous anchors formed into one side of the liner during manufacture. This mechanical interlocking provides excellent resistance to hydrostatic backpressure while minimizing deformation of the liner as temperatures fluctuate.

3. Suitable for cold and very hot weather installation

Most liquid-applied coatings require strict adherence to temperature and humidity limitations during application to reach full cure. Coatings tolerant of temperatures below 50 or 60°F offer limited chemical resistance and moisture tolerance. The same coatings might react too quickly for practical use over 80 or 85°F.

HDPE liners are an extruded sheet product and do not cure in the field, enabling their use in very cold and very hot weather. However, welding operations are sensitive to moisture. Humidity levels and dew points need to be monitored when the liners are being welded.

4. Can be prefabricated, precast to save construction time

Prefabricating or pre-casting the HDPE liners can save field construction time and avoid variable site conditions during welding and concrete casting operations, respectively. Smaller structures such as manhole sections, trench segments, and sump boxes are most conducive to prefabrication and pre-casting, though large tanks have been successfully pre-cast in sections.

5. Can be welded to inlet pipes, trenches for leak-tight seal

Inlet pipes and trenches lined with HDPE can be welded to lift stations and manholes lined with HDPE, provided the grades of HDPE are compatible. In contrast, a coated concrete manhole or lift station couldn’t be welded to plastic sewer pipes. The leak-tightness of such an interface would depend upon a mechanical coupling, and the risk associated with these out-of-sight, out-of-mind fittings leaking underground is not terribly attractive.

Anchored HDPE liners do not rely on this type of surface adhesion. The liners are mechanically locked into the concrete surface by means of numerous anchors formed into one side of the liner during manufacture. This mechanical interlocking provides excellent resistance to hydrostatic backpressure while minimizing deformation of the liner as temperatures fluctuate.

Conclusion

There are good reasons to use anchored HDPE liners instead of coatings in sewer manholes and lift stations—longevity, groundwater resistance, installation weather tolerance, construction time savings, and weldable pipe connections. For optimal design, the sewer pipes and appurtenances are best considered together, not just as a means of getting wastewater from point A to point B, but as integral components of a critical containment system.